Pipe Thread Sealants, Primers and more from Oatey

At Howell Pipe & Valve Supply, we stock the full range of Oatey and Masters products, often at lower prices than the big box stores. In this blog post, we’ll show you how Oatey products can help you in your various plumbing projects.

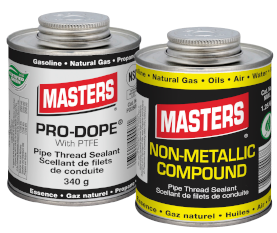

Pipe Thread Sealant

One of the most common and essential products for any plumber is pipe thread sealant, which prevents leaks and corrosion in threaded pipe joints. Oatey offers a wide range of pipe thread sealants, from the classic Pro-Dope with PTFE to Oatey Non-Metallic Compound. Whether you need a sealant for metal, plastic, or mixed materials, Oatey has you covered.

To use pipe thread sealant, you need to apply it evenly and generously on the male threads of the pipe. First, you need to tighten the joint by hand, and then use a wrench to make it snug. Don’t over-tighten the joint, as this can damage the threads and cause leaks. You can test the joint by running water through it and checking for any drips or moisture. If you see any leaks, you can try to tighten the joint a bit more, or disassemble it and reapply the sealant.

Pipe thread sealant is not only useful for plumbing, but also for other applications that involve threaded connections, such as gas lines, air compressors, sprinklers, and more. Just make sure you use the right sealant for the right material and pressure. When working with gas lines, you’ll also want to use Masters Gas Leak Detector, to check your connections are solid. If in doubt, one of Howell’s product specialists will be able to provide the right solution for your job.

Cutting Oil

Another product from Oatey in stock at Howell is cutting oil, which lubricates and cools the cutting tools and the metal pipes. Cutting oil helps to extend the life of the tools, reduce friction and heat, and produce a smooth and clean cut.

To use cutting oil, you need to apply it liberally on the cutting tool and the pipe before and during the cutting process. You can use a brush, a spray bottle, or a drip bottle to apply the oil. You also need to wipe off any excess oil from the pipe after the cut, and clean the tool with a rag.

Cutting oil is not only useful for cutting pipes, but also for drilling, tapping, threading, and reaming metal. Cutting oil can help you create precise and smooth holes and threads in metal, and prevent the metal shavings from clogging the tool or the pipe.

Cements and Primers

Another product that is essential for plumbers is cement and primer, which are used to join plastic pipe and fittings. Cement and primer create a strong and permanent bond between the plastic surfaces, and prevent leaks and separations. Oatey offers a wide range of cements and primers, for different types of plastic pipes, such as PVC, CPVC & ABS.

To use cement and primer, you need to follow these steps:

- Cut the pipe to the desired length, and remove any burrs or rough edges with a deburring tool or a file

- Dry-fit the pipe and the fitting, and mark the insertion depth on the pipe with a marker.

- Apply the primer to the pipe and the fitting, using a brush or a dauber. The primer will soften and clean the plastic surfaces, and prepare them for the cement.

- Apply the cement to the pipe and the fitting. The cement will melt and fuse the plastic surfaces, creating a strong bond.

- Insert the pipe into the fitting, up to the marked depth, and twist it slightly to spread the cement evenly. Hold the joint for a few seconds, until the cement sets.

- Wipe off any excess cement from the joint, and let it cure for the recommended time, depending on the type and size of the pipe and the temperature and humidity of the environment.

Cement and primer are not only useful for joining plastic pipes, but also for repairing cracks and holes in plastic pipes and fittings. Just make sure you use the right cement and primer for the right type of plastic and follow the instructions carefully. Again, Howell is here to help.

Solder

Solder is another essential accessory, which is used to join copper pipes and fittings. Solder is a metal alloy that melts and flows into the gap between the copper surfaces, creating a strong and watertight seal. Oatey offers a variety of solder, such as 95/5 Lead Free Solder, 97/3 Lead Free Solder and Silver Lead Free Solder.

TL;DR

Howell stocks the whole range of Oatey products, designed to make your plumbing and heating projects easier and faster. While they are widely available, Howell is confident we have the best price available. Couple that with our expert advice, and you’ll be wondering why you were ever shopping at a big box hardware store!

If you have any questions or comments, feel free to fill in the form below. Thanks for reading, and happy plumbing! 😀

Sources

- Oatey | Cements, Primers & Cleaners – www.oatey.ca/products/cements-primers-cleaners

- Oatey | Thread Sealants – www.oatey.ca/products/thread-sealants

- Oatey | Copper Installation – www.oatey.ca/products/copper-installation